Customer challenges

- During routine pressure/temperature logging, the incumbent service provider was unable to retrieve logging tools from the client's geothermal wells (>300OF)

- Assuming there was a casing integrity issue, the client sought an alternative solution to running gauge rings or a caliper log

Expro Excellence

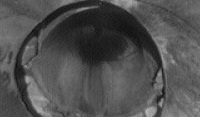

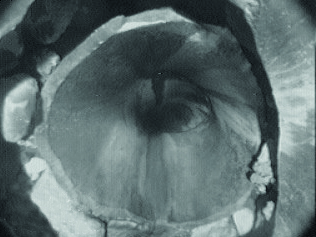

- Expro's high temperature downhole video was deployed to 971 feet (325OF) and confirmed parted 13 3/8" casing, causing rock and cement entering the wellbore and trapping the logging tools

- Running additional logging tools could have potentially been caught in the split casing and either damaged or irretrievable

Value to client

- Running the high temperature camera saved the client 16 hours of rig time and two runs downhole

- Visualisation of the parted casing provided detailed images of rock and cement through the gapping split enhanced decision making for cost-effective remedial work

- The client now routinely deploys Expro's downhole video cameras within their maintenance programme (up to twice a year in older wells) due to the fluids in geothermal wells being highly corrosive - invaluable data avoids costly repairs (for example c. $1.5 million to repair the well or c. $5 million to cement the well)