Customer challenges

- Expro was approached by a long standing, major operator to develop a solution to restart production, for a gas injection well which indicated a leak between the A and B annulus

- This was causing the customer both well integrity and safety issues, resulting in lost production and revenue

- The customer did not have the integrity required in the production of the well and as a result they could not use gas lift

Expro Excellence

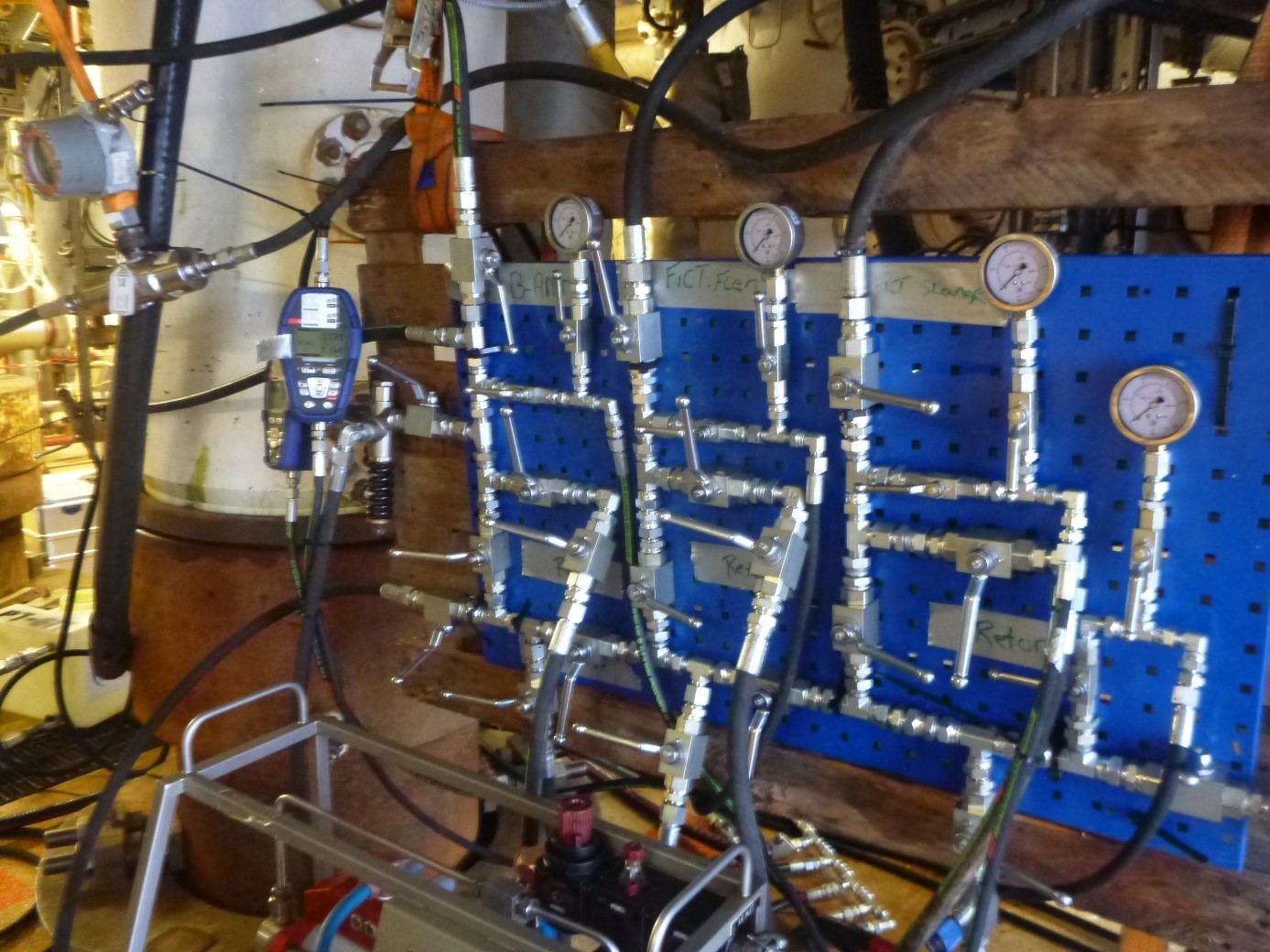

- Expro offered a bespoke solution with the placement of 360º low-density sealant in the B-annulus. (The low density sealant was placed in the annulus fluid allowing the sealant to float up to the leakage point on top of the B-annulus)

- Expro developed a bespoke fluid injection tool in collaboration with the customer to fit this well. The tool was used to evenly distribute fluid in the annulus of the LD seal (360º)

- Expro prevented the customer from having to hire a jack-up rig for the re-completion of the well

Value to client

- Expro secured a 360º placement of the sealant, no other competitors have the ability to enter and intervene the annulus, we are the only providers of this service

- Expro repaired the integrity issue without re-completion of the well (with out the use of a jack-up rig, saving the customer in excess of $1M). This significantly reduced the customers cost

- After the project was completed, the customer was able to commence gas lift and put the well back into production with 3,500 bbls/day

Expro helped increase recovery through restoring:

- Gas lift

- Well integrity

- Production

- The sealant was placed in the B annulus to prevent blocking gas injection in the annulus. Pressure testing to 90 bars was achieved from the annulus resulting in restored gas injection for the customer

- Expro's solution was developed in cooperation with the customer and this bespoke solution resulted in rapid mobilisation