Customer challenges

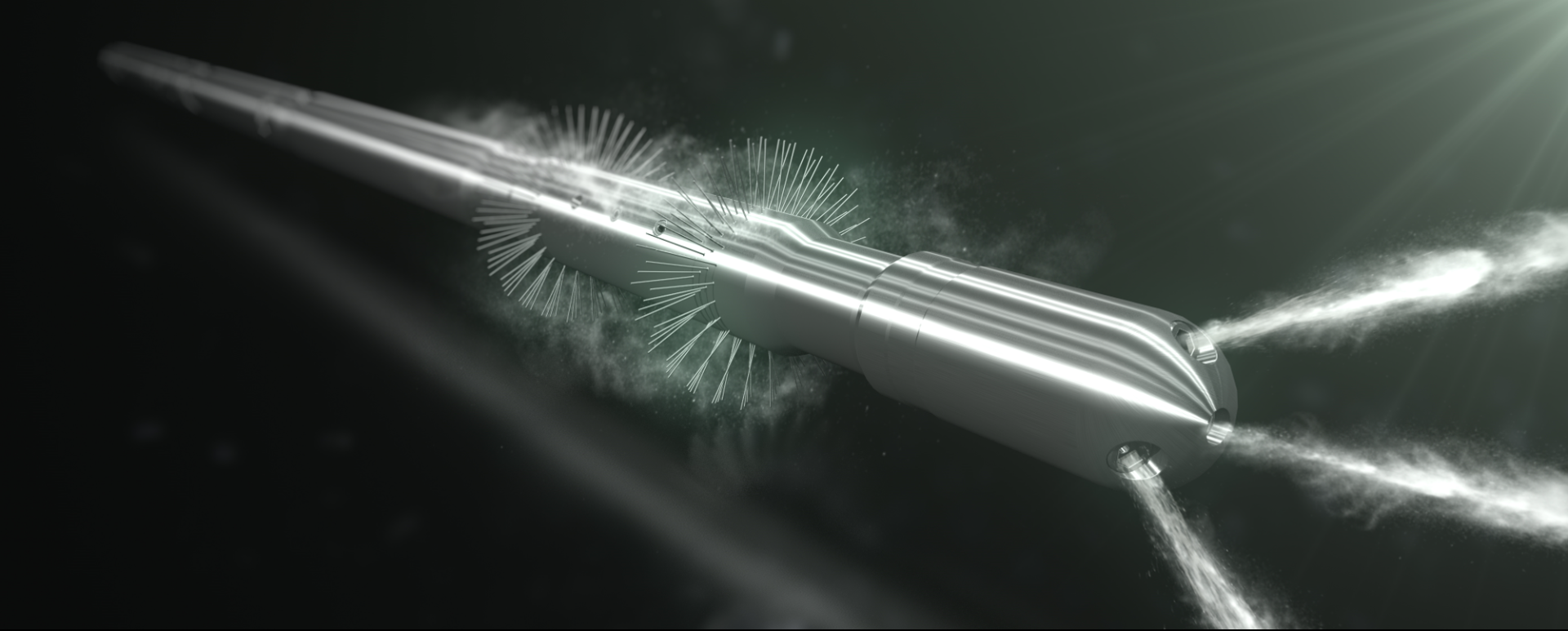

- Customer had a 2 3/8" injection string tubing retrievable injection subsurface safety valve (iSSSV) in the stuck open position

- Previous mechanical intervention attempts with conventional brushes and exercise tools were unsuccessful

- A camera run performed identified significant deposits of a heavy grease like substance along the length of the iSSSV which was believed to be preventing the flapper from operating

- CoilHose was selected as the optimum method for jetting and fluid circulation in order to reinstate the integrity of the iSSSV

- Contingency operations involved further mechanical intervention to lock out the iSSSV and set an insert valve

Expro Excellence

- Bespoke engineered solution deploying the latest Expro technology

- A collaborative approach to developing the well programme with the customer

- Pre-mobilisation SIT ensured confidence in the effectiveness of the proposed jetting solution

- Multi-disciplined crew received commendation for contribution to the platform safety processes

Value to client

- All programme objectives were achieved and integrity restored to the iSSSV

- Ability to maintain maximum thru bore of 2 3/8" tubing string without the need to lockout iSSSV and set insert valve

- Safeguarding of future production from the well

- Two runs performed that included five 'jetting passes' with no miss runs

- Minimal footprint and rig up time versus conventional coil tubing allowed increased operational efficiency