- Home

- Products & services

- Well Construction

- Well Flow Management

- Subsea Well Access

- Subsea Test Tree Assemblies

- Intervention Riser System

- Riserless Well Intervention System

- Light Well Intervention Vessel

- PRT Offshore

- Motion Compensated Coiled Tubing Lift Frame

- Inline Compensator 600T

- Inline Compensator 220T

- ProFrame™ Coiled Tubing Lift Frame

- HOSS™ Wireline Lift Frame

- Gate Valve Flowhead

- Surface Test Tree

- Quick Union

- Lubricator Valve

- Subsea Landing String

- Subsea Controls

- ProComp™ Tower

- Intervention Work Tower

- Blue Sky Tower

- Accessories & Rental Tools

- Contact Us

- Well Intervention and Integrity

- Sustainable Energy Solutions

- Case studies

- Media hub

- Careers

- Citizen of the world

- Contact

- Our 2023 Sustainability Review

- About Us

- Investors

- Locations

ControlCure®

Engineered cement hydration

Shallow hazards can pose significant risk to conventional cement jobs and traditional techniques of using managed pressure cementing, complex slurry trains and expensive additives can add substantial cost to well construction projects. Mitigate drilling risk, lower project cost and improve cement hydration with ControlCure®.

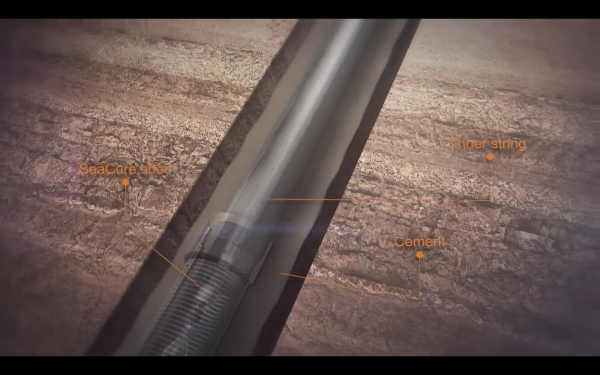

ControlCure® is the engineered process of circulating a temperature-controlled fluid after cement slurry placement at different points in the casing bore ID via the inner string conduit to elevate, cool or control the cement setting environment at specific zones in the wellbore.

Like QuikCure®, ControlCure® utilises SeaCure®’s inner-string technology as the circulating string.

Engineered cement hydration with ControlCure®

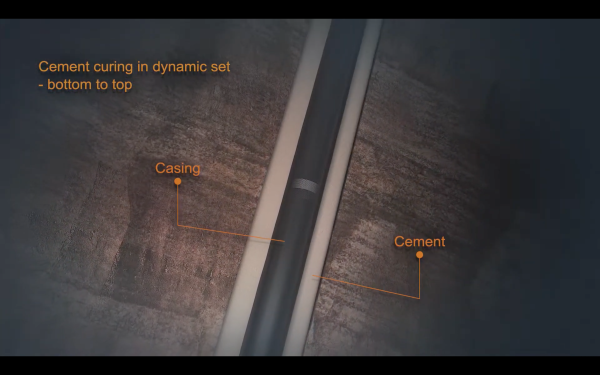

Ambient mud line temperatures can be near freezing for subsea drilling projects, especially in deep water basins. These low temperatures can drastically extend cement setting times for top hole sections. Adverse drilling subsurface conditions, such as shallow hazards, may make traditional cementing processes more costly and time consuming.

Waiting on cement (WOC) can allow for sufficient compressive strength build-up in the annular cement slurry to provide a strong foundation for the well and for precise alignment for the well control package, including the subsea blowout preventer to ensure its functional capability.

Through the addition of multiple circulation paths within the inner string, at varying depths, and/or controlled circulation rates of engineered temperature fluids, ControlCure® influences the temperature profile of cement slurry in the casing annulus. The engineered capability of slurry temperature offers a unique cement setting program, ensuring hydrostatic pressure is always maintained on shallow hazard zones whilst safely isolating them.

Controlling the setting temperatures of both the lead and / or tail cement slurries enhances the set-cement properties, reduces the potential for gas or water influx, eliminates micro-annulus, reduces waiting on cement (WOC) time and overall saves rig time and reduces well construction cost.

ControlCure® Value

- Design cement hydration to maintain over-balance

- Intelligent managed pressure cementing

- Mitigate shallow hazard risks

Find detailed information about our products and services.